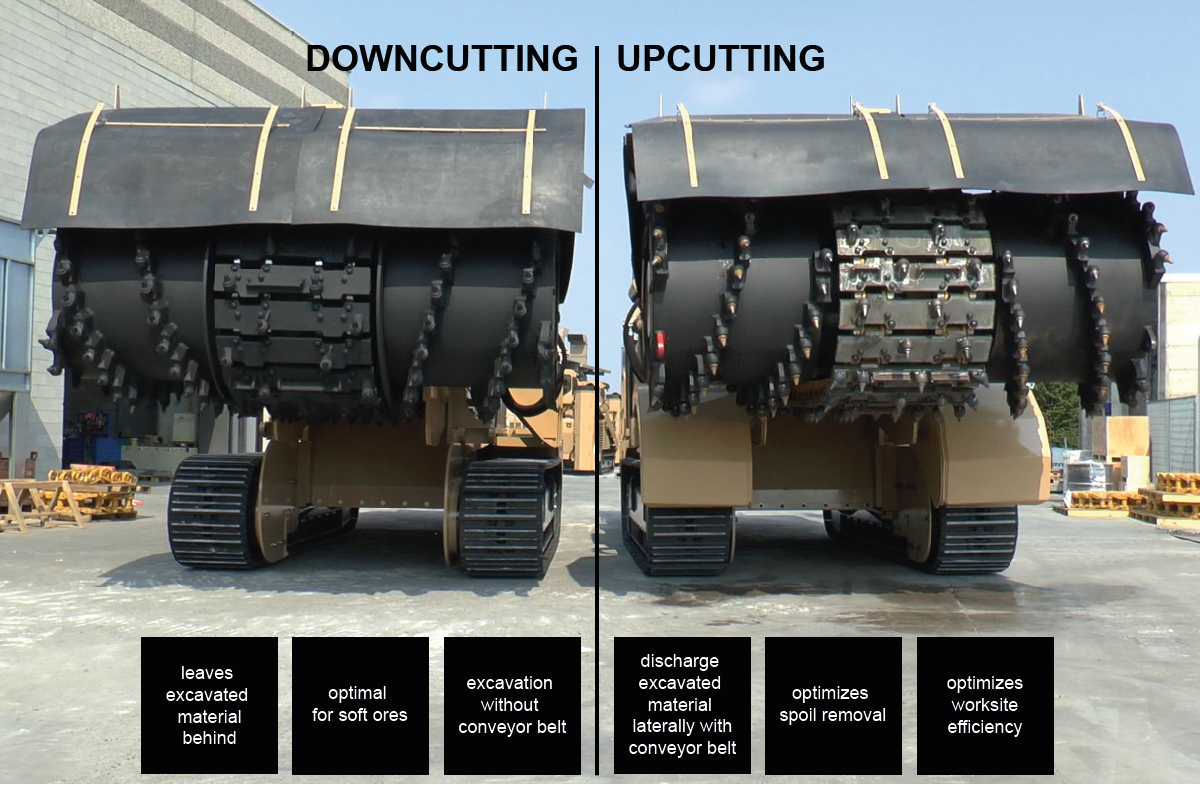

Tesmec surface miners can work up-cutting and down-cutting by changing the attachment. Choose the right excavation mode according to your needs.

| |

DOWNCUTTING |

UPCUTTING |

|---|

| Advantages |

- Down-cutting version leaves the excavated material behind the machine. Material can be stockpiled or removed immediately. This version is optimal for soft ores such as gypsum, coal, salt.

- Excavation without conveyor belt In the down-cutting mode the absence of conveyor belt allows to cut vertical sidewalls, reduces the width of the machine and results in increased efficiency, lower costs and no need for maintenance.

|

- The up-cutting version leaves a clean and flat surface by discharging the excavated material laterally with a conveyor belt.

- The area can be immediately re-cut, without any preparation. This is a big advantage as it optimizes the spoil removal and worksite efficiency. There is no need for immediate cleaning of the working area.

- The Rock Hawg can excavate several times in the same area, thanks to lateral discharge of the excavated material.

|

| Working mode |

- The teeth hit the rock from the top downward and the impact increases the efficiency of excavation if the rock is brittle (highly fracturable).

- All the available power of the Rock Hawg is used for excavating the rock.

- Excavated material is not mixed. Different materials can be separated during the loading phase.

|

- The teeth hit the rock from the bottom upward. Reduced impact, less vibrations and increased capability to excavate solid, harder rock.

- The total cutting force is increased by crawler pull.

- Excavated material is loaded and stockpiled beside the excavated area.

|

| Most suitable for... |

Fractured rock mass Brittle (Fracturable) rock From weak to medium strong rock |

Unfractured rock mass Tough (not fracturable) rock From medium strong up to very strong rock |

Download the leaflet