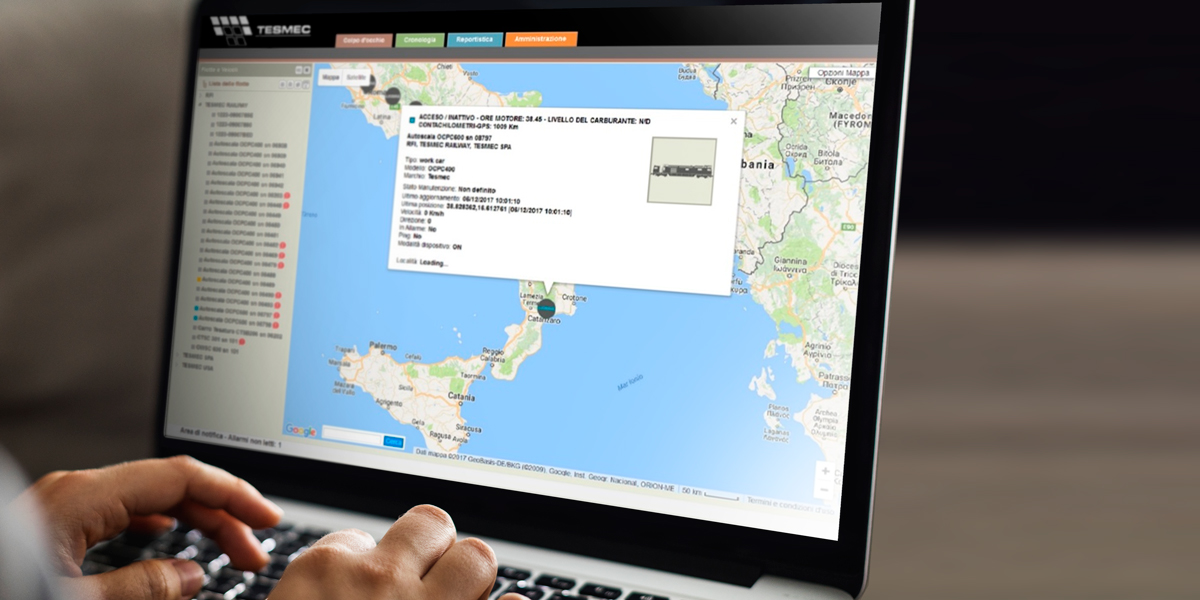

Re.M - Machine and fleet remote monitoring for railway equipment

With the aim to improve each machine’s performance and support its customers, Tesmec developed a remote-control module to monitor the parameters of the railway vehicles.

The Re.M (Remote Monitoring system) provides operating, maintenance and troubleshooting information allowing 24/7 monitoring of fleets of vehicles, optimization of maintenance operations and high efficiency in service activity. It means that in the event of a fault, technicians or managers can start the troubleshooting process and decide what type of crew and what parts will be most likely required, before heading out for the machine.

Thanks to a robust and reliable electronic unit with high performance microprocessor and a compact GPS antenna/GSM/HSPA +, the system displays on a map the location of the vehicle allowing the remote monitoring of the fleet operating parameters:

- Machine data remote monitoring (engine hours, mileage, fuel consumption..)

- Geolocation of the vehicles

- Diagnostics (operating parameters, active alarms, environmental conditions, conditions of use, etc.)

- Operating conditions, working cycles, itineraries/chronology Any of the available information can be accessed from a remote PC anywhere at any time, with the sole need of an Internet connection.

BENEFITS

- Economic

- Reduction of testing hours

- Optimization of the project

- The preventive maintenance operations reduces the “cost linked to the fault” (lack of service, lack of production)

- Reduction of the “cost of the fault” (replacement of components, damages).

- Monitor machine health, saving costly engine or transmission repairs due to operator error and inattention.

- Efficient

- Increase Productivity and Profitability

- Time efficiency thanks to constant interaction with users

- Increase overall efficiency with visibility of equipment productivity, location and history

- Get accurate productivity measurements to help improving each machine’s performance.

- Safe

- All the information about your fleet or about a single machine and operators.

- Management and execution of working operation during an emergency condition

- Decreasing human error and inaccuracy

- Sustainable

- Management of data concerning engine hours, mileage in order to reduce emission and fuel consumption

- User friendly digital panel which guarantees automatic control, accuracy, precision and safety.